Projects

Projects

Featured projects

In the last 13 years, WCC Crane Solutions has serviced over 2,000 projects ranging from the design of special application uses for cranes and hoists as well as structural engineering projects, various custom design projects and turnkey engineering solutions.

Clients have included manufacturing industries, mines and sawmills throughout British Columbia, Alberta, Manitoba and Alaska, Washington State, and Oregon.

Below we have chosen some past projects which will highlight the breadth work and engineering solutions we can provide:

Project: Colby Grapple Crane Assessment

Location: Zellstoff - Celgar, Castlegar, B.C.

Project Task:

- Runway Structural Capacity Assessment,

- Hoist Structural Assessment,

- Hoist Center Gravity Calculations,

- Trolley Assessment and Calculation and

- Crane Bridge Assessment.

Project: VANOC 2010 Custom Design Lifts

Location: B.C. Place, VANOC, Vancouver, B.C.

Project Task: In association with 'David Atkins Enterprise' and 'Show Canada'

- Suitability analysis and mechanical certification for inner and outer lift,

- Suitability analysis and mechanical certification for automated East tilting platform, performer lift and scissor lifts,

- Suitability analysis and mechanical certification for central cauldron winch and cauldron arm with slewing ring.

Project: Custom Design Temporary Theatre Crane

Locations: River Rock Casino, Richmond, B.C., & Hard Rock Casino, Coquitlam, B.C.

Project Task: In association with 'Gala Systems' and 'Kaverit Steel and Crane'

- Complete design and project management for the 3 tonne special semi gantry - monorail theatre crane:

- Created a step by step manual for assembly and disassembly of the crane unit when moving between the locations.

Click to see a video of a time-lapse of the theatre crane installation at Hard Rock Casino: Link

Click to see the finished theatre: River Rock Casino & Hard Rock Casino Vancouver

Turnkey Solutions

Turnkey Solutions

We take pride in providing specialized turnkey solutions to our clients. A "Turnkey Solution" is a project where the contractor undertakes the entire responsibility from design through completion and commissioning. The client only has to turn the proverbial key to make everything function as it should.

Please see below for examples of projects where we performed and managed all aspects of the project:

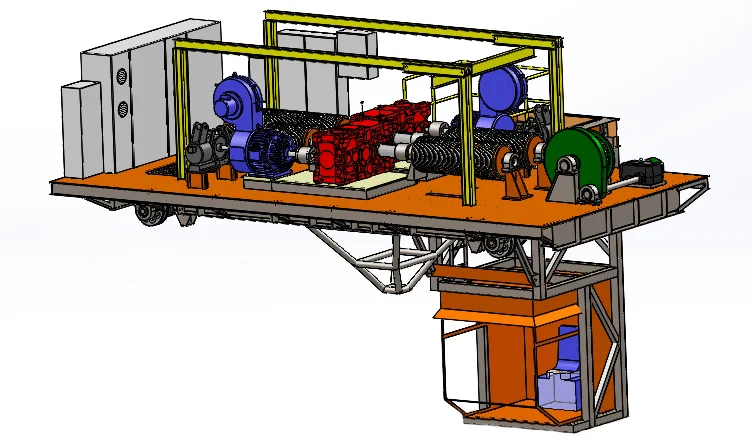

Toyo Pumps - Heavy Pump Production Assembly

Issue:

The manufacturing process needed to be improved and streamlined. Heavy reliance was placed on forklifts and small gantry cranes for lifting, which resulted in performance issues and safety concerns.

Solution:

We were hired to improve the whole system. From inception to installation, we put several solutions in place: 2 overhead cranes, several jib cranes and a special custom lift system for the pump assembly process.

Result:

Our client saved time by not having to be involved in the planning processes. The overall output performance was drastically increased and overall worker safety was improved.

GVRD Iona - Maintenance & Welding Shop

Issue:

The cranes in use at the time were over over 50 years old. They had low lifting capacity and only one speed (slow).

Solution:

From inception to installation, we put in place: a complete runway and installed a crane with a higher capacity with multiple speeds.

Result:

In addition to time savings, the overall output performance was drastically increased and overall worker safety was improved.

City of Richmond - Pump Maintenance Shop

Issue:

Our client was working with a number of difficulties; the maintenance process was antiquated and they were using forklifts for all their lifting needs - not a safe process! In addition to that, the shop floor space was limited and could not accommodate a standard crane installation.

Solution:

We create a custom design in Solidworks, presenting our customer with a 3D model view. From inception to installation, we put in place: a full under running overhead crane with runway.

Result:

In addition to time savings, the overall output performance was drastically increased and overall worker safety improved.

Agropur Cooperative - Dairy Cooperative; Burnaby, B.C.

Issue:

Installation of a 2 ton monorail in a heavily sterilized room, without the use of a scissor lift or forklift.

Solution:

WCC was involved from inception to completion including design, material procurement, fabrication, and construction.

Result:

A successfully installed monorail and accompanying support structure without compromising the sterile integrity of the room while delivering on-time and on-budget solutions.

Recommendations

Recommendations

“Working with a professional crane company like WCC included all aspects of replacing my existing crane. WCC provided engineering to upgrade the crane capacity, crane and material procurement, experienced labour to install and completely followed up with crane testing and certification. All I had to do was watch!”

“I first contacted WCC Crane Solutions in 2005 to design and certify a custom spreader bar to be used with our overhead cranes. Since then they have helped us with all our engineering and certification needs. Rano and his team are professional, reliable and have always found practical, cost effective solutions to some very difficult challenges. They have helped us design many custom “below the hook” lifting devices, custom lifting machinery, racking and structure certifications, load testing, overhead crane upgrades and new crane purchases. Rano stands behind his designs and stamped certified drawings are provided with everything. WCC Crane Solutions Inc. provides us with solutions that work and great customer service.”

“Everyone here is very impressed of the work you all (WCC) did to get these stops fabricated and installed in such a timely manner. I have made a point of praising WCC in the presence of the superintendents/managers here just so that your efforts are recognized. Thanks for the help.”